In the fast-paced world of modern machinery, AB GEARS was born from a passion and commitment to precision power transmission technology. Our website, abgears.com, serves as a vital connection between us and our global partners, offering in-depth expertise and extensive experience in planetary gearboxes and their applications.

AB GEARS specializes in the design and manufacturing of high-precision planetary gear reducers, serving industries such as automation, machine tools, robotics, packaging equipment, and new energy. Headquartered in Taiwan with a global outlook, we work closely with distributors, system integrators, and OEM clients across Asia to deliver stable, durable, and efficient gearbox solutions.

abgears.com is more than a product showcase — it is our frontline for technical support, industry insights, and customer engagement. Whether you are searching for the right gearbox model or exploring custom development, our website provides a direct channel for timely assistance and communication.

We believe that every rotation of a gear is a perfect dialogue between engineers and machinery. At abgears.com, we warmly invite you to join us on this journey of precision motion and let us become your most trusted power transmission partner.

Energy efficiency and environmental protection

Use high-efficiency motors, reducers and improved control algorithms to reduce energy consumption, while considering the use of environmentally friendly materials

Software and data analysis

Analyze and optimize data during the production process, such as using SCADA systems for monitoring and optimizing production schedules through AI algorithms to achieve intelligent decision-making.

Modular design

In order to improve maintainability and scalability, the automation system should use modular design as much as possible. This allows for easy equipment upgrades and maintenance.

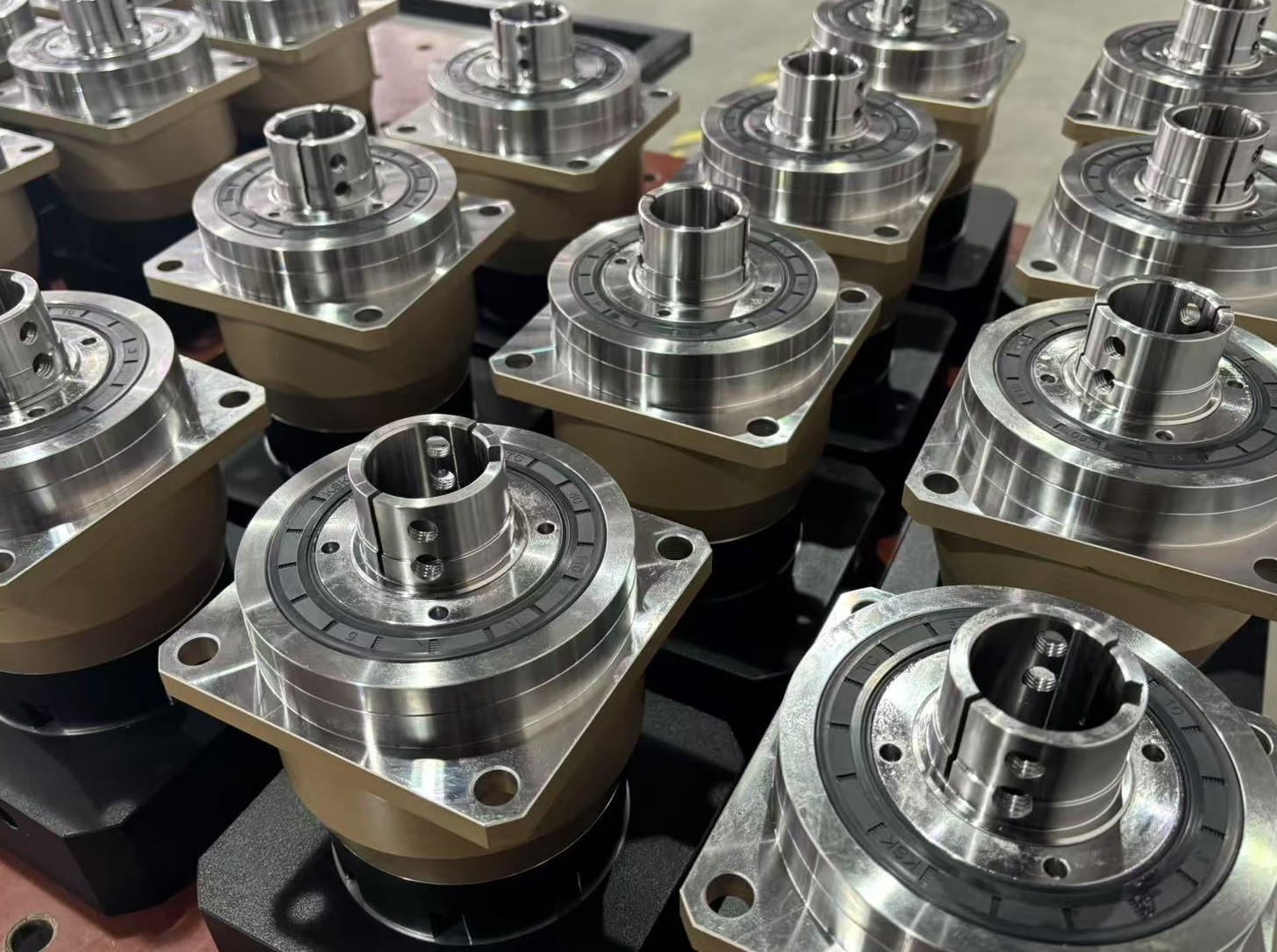

Recently released new series of products

New TPG 40,60,90,120 SERIES!

Adopting special material flexible inner gear ring, the highest precision is <1 Arc-Min

Crossed roller bearings are used to achieve high rotation accuracy and low runout

Suitable for equipment that needs to be started and stopped frequently

Customer case

Adjusting the performance of the reducer to suit different customer usage conditions is an important step. For different needs

1. Enhance the reduction ratio

Adjusting the reduction ratio can directly affect the output torque and speed to meet the needs of different equipment. .

2. Select the appropriate gear material and precision

The selection of gear material and processing accuracy will affect the life and operational stability of the reducer.

3. Optimization of structural design

According to different working conditions, the shell design of the reducer can be adjusted or the heat dissipation structure can be changed. For example, in high-temperature or high-speed operating environments, design an effective heat dissipation system, or use lighter shell materials to improve the stability of the reducer.

Depending on the specific use environment and needs, these adjustments can be applied separately or combined to meet the customer's specific requirements and extend the service life of the reducer.

Micro servo special reducer

The reducer is specially designed for micro servo motors with power below 40W, and can withstand a maximum input speed of 10000RPM

Reducer for electronic parts sub-station assembly

The reducer needs to have a high degree of accuracy, stability and high-speed operation capabilities to ensure that the robotic arm or automation device can be accurately positioned during assembly, handling and positioning.

Reducer for printing press

Reducers for printing machines have very high requirements in terms of high speed, stability and precise transmission. Reducers need to have good torque transmission capabilities, operational stability and long-term durability.

Copy Right @WINTEC trans-technology Co.,Ltd Right Reserve