How to estimate the service life of the gearbox

When estimating the service life of a gearbox, the engineering community usually uses calculation formulas based on rolling bearing life theory (such as L10 life) and gear life theory. The following are the two main methods:

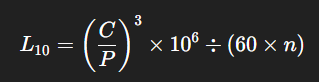

1. Rolling bearing L10 life formula (commonly used in gearboxes)

L10 life refers to the minimum life that 90% of mechanical components can achieve (expressed in hours):

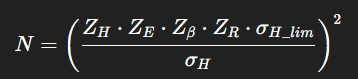

2. Gear life prediction (based on fatigue life)

The life of a gear is mainly determined by **tooth surface fatigue (pitting) and tooth root fatigue (fracture)**. The following theories are commonly used for prediction:

L10: Expected life (hours)

C: Rated dynamic load of the bearing (kN)

P: Equivalent dynamic load (kN)

n: Speed (RPM)

This formula assumes normal operating conditions and proper lubrication.

Tooth surface fatigue life calculation (simplified formula):

N: number of cycles that can be tolerated

σH: actual tooth surface contact stress

σH_lim: tooth surface fatigue limit stress

Zh, Ze, Zβ, Zr: correction factors (considering tooth shape, material, lubrication, load, etc.)

🛠 Common practices in practice:

Use life charts or data provided by manufacturers

They often provide life estimates under different loads and speeds based on the above theory and test data.

Use ISO standard formulas

Such as ISO 6336 (for gears) and ISO 281 (for rolling bearings) for life estimation.